We scrutinize the quality of all metals, fabrics and resin materials to secure high quality and minimize the environment impact.

- Acceptance testing

-

At the stage of purchasing materials, we conduct stringent testing to reject non-standard materials or others that do not conform to specifications.

- History management

-

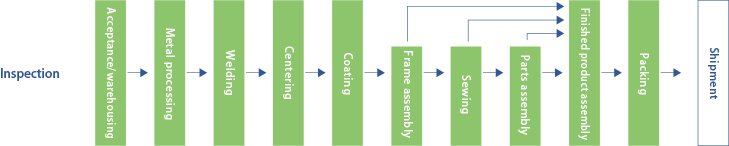

From acceptance and assembly through to shipment, we perform lot management of materials and parts.